Kevin Hardy founded Global Ocean Design after a career at the Scripps...

A column about the Technologies, Strategies, and Use of Ocean Landers Battery Equalizer 24v

Lithium-Polymer batteries offer a safe and robust option for portable electrical power. As we collectively have gained experience, application parameters have been refined, defined and improved. Though ubiquitous in everyday life, their acceptance has not quite outrun a troubled past. LiPos have now flown on crewed Space-X spacecraft and are installed on the International Space Station. The global automotive industry is undergoing dramatic change with new battery developments that follow the personal computer and cell phone industries. The Tesla Powerwall, which uses a stack of LiPos, allows homes to get off the grid when the grid goes down. WHOI’s DSV ALVIN, James Cameron’s DSV DEEP SEA CHALLENGER, and Triton Submarine’s TRITON 36,000/2 (DSV Limiting Factor) submersibles are powered by pressure compensated LiPo battery modules. In 2019 and 2020, Japan launched two new diesel-electric submarines, Taigei, or “Great Whale,” and Toryu, or “Fighting Dragon,” equipped with lithium-ion batteries, making the submarines capable of cruising silently submerged for longer.

Like different animals at the San Diego Zoo, it is important to recognize LiPo’s are simply different than lead-acid or alkaline batteries. They have their own distinguishing behaviors. I admit to some apprehension when I began studying, then learning-by-doing with LiPos. I started out with LiPo batteries inside of fireproof charging bag, on a concrete floor within a small cinderblock bunker 6-feet away from everything else. I moved to a big clay garden pot with a clay drain pan for a lid. I monitored temperature, and voltage. I read everything I could. I followed up on promising leads. It was DreamWorks’ “How To Train Your Dragon”. I needed to know. Safety remained paramount, as I began to get a handle on the technology a lot of others were already using.

I have now used LiPos for several years in a variety of at-sea applications. The more you learn, the more successes you have, and the more possibilities present themselves. I respect their energy density, but also their willingness to do a job. There is a large body of work describing fundamentals of LiPo cells and their application. This article will cite some of them.

In brief, always treat LiPo’s with the respect they deserve. It is crucial to stay within the industry recommended operational parameters. The terrible tales of weekend RC enthusiasts can partly be blamed on those end-users straying outside the prescribed boundaries to gain a few more minutes of flight time, or trying to get one more flight in by fast-charging above the recommended max rate. Sometimes it’s a lousy battery they got at a cheap price. Sometimes they don’t have the right devices to protect and maintain the batteries as they should be. Some Basics on Li-ion and LiPo batteries

Lithium-ion and Lithium-polymer batteries are rechargeable, secondary cells with similar chemistries. They can be used for the same high-power applications. They are distinguished by different electrolytes and packaging.

Lithium-ion and Lithium-Polymer are completely different from primary, non-rechargeable lithium cells. For one, lithium polymers use an intercalated lithium compound for their electrodes, not metallic lithium, and therefore are more stable. They are also not hazardous if exposed to water. Lithium-ion cells use a liquid electrolyte, and are encased in a cylindrical stainless-steel housing. The well-known 18650 cell is an example.

Lithium-polymer (LiPo) cells use a gelled electrolyte and are vacuum sealed inside a soft plastic pouch. This is known as a “prismatic cell”. There are several LiPo chemistries, but the most common for prismatic packs is Lithium Cobalt Oxide. The chemistry is specified in the MSDS for that battery. A stack of prismatic cells maybe be bound together using a shrink wrap, for lightweight applications, or inside an injection molded hard plastic casing to provide puncture resistance.

Compared to alkaline cells, LiPo’s have lighter weight, higher capacity, higher discharge rate, and are less affected by cold temperatures as may be found deep. Cycle life can be 100’s before battery capacity is reduced to ¾ of its original capacity. A LiPo configuration is specified by the number of prismatic cells, and how they are connected, that is the numbers of cells in series and in parallel. A “6S1P” means there are 6 cells in series, and only 1 stack, with none in parallel. Virtually all prismatic batteries are wired with all cells in series, and so the configuration is simply referred to as “6S”, with the “1P” understood.

About voltages: The nominal voltage of a battery is the number of cells x 3.7v/cell, the mid-point voltage of a battery pack. A 6S battery is described as 6 cells x 3.7v/cell = 22.2v, though a full charge is 25.2v.

LiPo batteries have four key voltages to know:

Figure 2. State of Charge versus LiPo Pack Voltage (Chart courtesy of Mark Forsyth, RCGroups.com)

Using a 10” polyamide sphere, I’ve made a positively buoyant 22v/20Ah (440Wh nom) rechargeable battery. That’s a car battery that floats.

LiPo quality varies between consumer and commercial grade batteries. Commercial grade batteries are made by paying attention to quality at every step, including selecting cells that match the characteristics of others in a stack. Consumer grade batteries are made by paying attention to cost. The difference is like buying batteries from Duracell versus Harbor Freight. Two commercial brands I tend to use are Gens Ace Tattu and Turnigy Graphene. One list of the top LiPo manufacturers can be found at <https://www.grepow.com/blog/best-rc-lipo-battery-for-2020.html>.

Figure 4. A Gens Ace Tattu LiPo battery. The LiPo battery characteristics of voltage, capacity, configuration, and max current rating are shown. More background information on GensAce/Tattu LiPo batteries may be found at <https://www.genstattu.com/bw/>. (photo credit: Gens Ace)

Because prismatic cells are vacuum sealed in a soft plastic pouch, they are pressure tolerant. There are no compressible materials on the interior so the rate of chemical reaction is unaffected by pressure. The matching BMS protection circuitry is likewise made of pressure tolerant components (See next section). I have immersed both in bags filled with mineral oil and tested them to 18,000-psi. They held up fine.

Placing a pressure compensated LiPo battery outside the hull means you only subtract the water weight from the buoyancy budget, rather than the air weight when it’s inside the hull. Just a SWAG, but for the same amount of buoyancy, a craft may be able to carry an additional 25% power. For more background details on LiPo’s, see Battery University <https://batteryuniversity.com/>; “A Guide to Understanding LiPo Batteries” <https://www.rogershobbycenter.com/lipoguide>; and “The care and feeding of LiPo packs” <https://www.promodeler.com/askJohn/How-To-Care-for-LiPo-Packs>. Follow your curiosity and you’ll find others. LiPo Protection circuitry

Here’s where I diverge from normal RC practice.

It is very important to balance charge a LiPo battery. This is because some cells have slightly higher internal resistance than others, allowing some to overcharge, while others undercharge, if not regulated. You’ll find a plethora of “balance chargers” that work fine. BUT, it is also important to balance discharge to prevent one cell from discharging faster than the rest for the same reasons, and plunging too low. A low voltage cut-out is not enough, as that measures the total voltage of the pack. One cell, hiding within the total voltage of the battery pack, can be depleted to the point of ruin, taking the whole battery with it. When that battery is placed on a balance charger next time, it will find the one that’s bad, and cancel the charge.

The solution is a BMS: Battery Management System, a board designed to protect every cell in your LiPo pack by keeping it inside safe operating regions. In addition to a charge/discharge balancing function, a BMS features over-charge protection (high voltage cutout), over-discharged protection (low voltage cutout), short circuit protection (disconnect the load), and over-current protection (selectable 20A, 30A, 40A). The better BMS designs draws less than 200uA. Figure 5. A LiPo protective circuit “Battery Management System” (BMS), protects individual cells in a LiPo pack during charge and discharge. A 5S LiPo battery is shown. (Photo credit: QSKJ Power Module Experts)

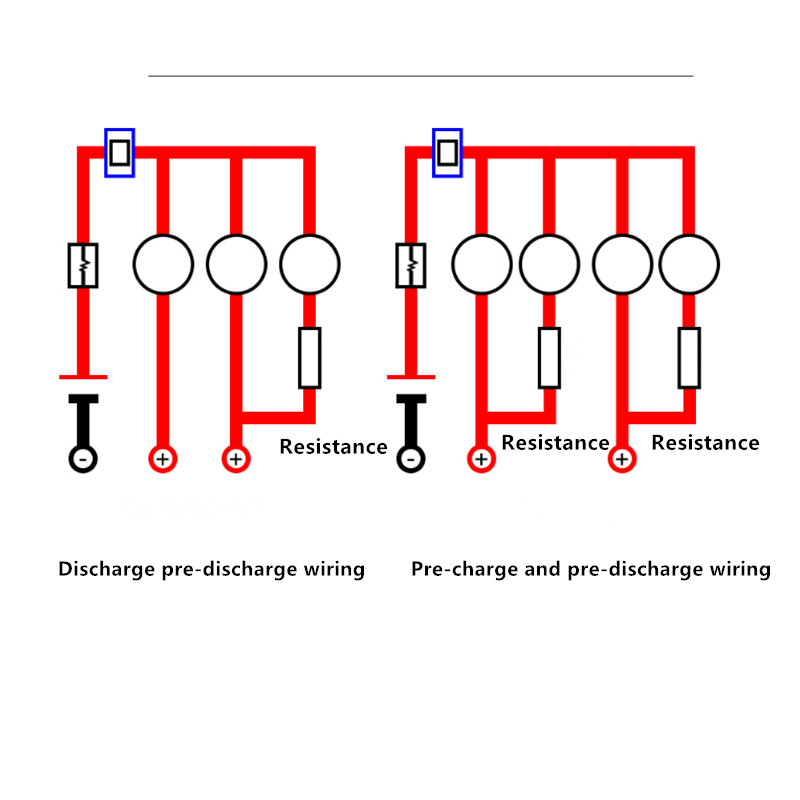

Another great advantage to the BMS is multiple identical batteries, each with its own BMS, can be tied together, positive-to-positive, negative-to-negative, in what is called a “voltage bus”. The parallel arrangement provides the battery rated output voltage, while adding the Amp-hour capacity together. The BMS also provides the ability to recharge the battery from a single power port without opening the housing. If a second battery pack for a deployed lander is on-hand, it can be charged slowly, which will extend the life of the cells.

Look closely at the SMT components used in assembly of the BMS board. Chances are good they are all pressure tolerant. Good news, this means a pressure compensated LiPo can have its side car BMS along for the ride.

Safety: A polyamide sphere is sealed with a vacuum. In the unlikely event any gas is generated, the sphere will simply fall apart. If submerged, saltwater will discharge the battery, but will not react with the polymer. If using a glass sphere from Nautilus Marine Service (Vitrovex): Pull the cap off the self-sealing purge port. The check valve will hold the interior vacuum, but pop out if there is an internal overpressure. Be sure to replace the purge port cap when done. If in a cylinder, a safety measure for outgassing is to remove the screws holding the endcap to the housing. An internal vacuum will hold the endcap on, and internal overpressure will push it out. If fitted with a self-sealing purge port, remove the cap. The internal check valve will hold the interior vacuum, but pop out if there is internal overpressure. Be sure to replace the purge port cap when done. Alternately, a Pressure Relief Valve (PRV), like those made by Deep Sea Power & Light or Prevco, could be used. A PRV should be placed at the bottom of a pressure case, similar to an entry hatch to an undersea habitat. When a PRV is open, it is open directly to the sea. PRVs have a cracking and re-sealing pressure, at which point water can dribble in if the PRV is pointing up. Another reminder for engineers is to be careful of dissimilar materials corrosion between the PRV and the end cap. We’ll discuss Housings more in a later issue.

Chargers Since each battery has its own BMS to balance charge individual cells, a smart unbalanced charger designed for LiPos is needed. These are notable in that they do not have the LiPo balance plug connector port. Figure 6. An unbalanced smart LiPo charger. Universal input allows use in any country or ship of opportunity. (Illustration courtesy of AA Portable Power Corp.)

A smart unbalanced LiPo charger provides LiPo under-voltage protection, so that if the LiPo battery’s voltage is <15.12V, the charger will not charge the battery as one or more cells are likely damaged. It also offers a second level of protection to the BMS for output short circuit protection, over-temperature protection, over-voltage protection, and reverse polarity protection. The smart unbalanced LiPo charger provides a constant current/constant voltage charging cycle. Figure 7. An unbalanced smart LiPo charger provides Constant Current (CC) initially, then shifts to Constant Voltage (CV) to complete the charge. (Illustration courtesy of Witold Maranda, PhD, Lodz University of Technology, Poland) Important Instruments to have

1. DVM, of course, then it gets interesting.

2. The LiPo ESR (Equivalent Series Resistance) Meter Mark II.

Easily the next most important LiPo diagnostic tool to have in the tool chest.

Internal resistance (IR) is the best predictor of battery condition. IR is measured in milliohms (mΩ). The lower the resistance, the less restriction there is current flow. High resistance causes the battery to heat up and the terminal voltage to drop under load. The LiPo ESR (Equivalent Series Resistance) Meter Mark II is the best meter on the market for judging the quality of lithium battery packs. Figure 8. The ESR (Equivalent Series Resistance) Meter Mark II. (Photo courtesy of Progressive RC)

The ESR meter provides the internal resistance of individual cells when removed from the battery stack, or an integrated measurement of the entire pack, including the BMS. The BMS adds a fixed offset to the battery IR. The ESR provides a direct readout of the Internal Resistance and Max Current the pack can deliver at the moment the measurement is made. Figure 9. The Internal Resistance (ABOVE) and Max Current (BELOW) can be measured and recorded for a new battery. These photos show a measurement of the condition of the full battery with BMS. If the estimated load is under 40A, this battery is fine. It is not necessary to hook-up to the balance plugs of the LiPo battery to make a general assessment, though it presumes the BMS is doing its job of balancing each cell. Should the net IR value increase from the initial measurement over time, the battery may need to be replaced. (Photos by Kevin Hardy)

The manufacturer advises measurements be made at the same temperature. ($150, Progressive RC)

3. The Computerized Battery Analyzer V Pro (CBA V Pro)

I’d definitely get this one, too. It’s used to test battery capacity and to accurately and automatically discharge a battery to a specific voltage for storage or shipping. Figure 10. The Computerized Battery Analyzer V Pro (Photo courtesy of West Mountain Radio)

The Storge and Shipping voltages are obtained by first charging the battery, then discharging to the specified voltage using the CBA V Pro Battery Analyzer. Specify the end voltage and the CBA will automatically stop when it reaches that voltage.

The CBA (Computer Battery Analyzer) V can also determine the actual capacity of the battery at different discharge rates. It can also test the Low Voltage Cut Out function (LVCO) of the BMS. Figure 11. The CBA provides a true discharge curve and capacity of your battery. Here, the green horizontal line at 18.00 v is the preset limit to shut off the discharge of the 6S battery (3.0v/cell). Instead, the BMS low-voltage cut-out (LVCO) kicked in at 19.20v (3.2v/cell). (Photo by Kevin Hardy)

To test a battery’s capacity at cold temperature, place it in a refrigerator and run the leads out to the CBA V. An indoor/outdoor thermometer will provide temperature. ($229, from West Mountain Radio <https://www.westmountainradio.com/>) 4. A 5-in-1 Cell Meter to test cell voltage: Figure 12. The Tenergy 5-in-1 cell Meter (Photo courtesy of Tenergy Power)

This meter measures voltage of individual cells and total battery voltage through the balance plug.The Tenergy 5-in-1 Cell Meter can display the estimated remaining capacity based on unloaded terminal voltage for LiPo battery packs. Use this meter to quickly check if your battery requires charging before use. It can also display the voltage of each individual cell, confirming balance condition.

For LiPo and Li-ion battery packs, this cell meter will display the internal resistance of each individual cell, providing a quick evaluation of the health of the battery. I would use this meter as a check against the ESR, but would trust the ESR as a better instrument for this important task. ($19, at Tenergy Power)

UNOLS on Shipboard LiPo safety

Four University-National Oceanographic Laboratory System (UNOLS), WHOI and USN documents maybe found at https://www.unols.org/documents/batteries.

Scripps Institution of Oceanography has a similar document at https://scripps.ucsd.edu/sites/scripps.ucsd.edu/files/basic-page-ships/field_attachment/2015/SIO.ShipboardLithiumBatteryGuidelines.Nov-2014.pdf Shipping:

IATA UN 38.3 restrictions apply. Good tip: Do not modify the LiPo batteries in anyway, and the UN 38.3 test certification document the manufacturer used to ship them to you still applies. They are required to give you a copy if you ask. FedEx and UPS publish their guidelines based on IATA Rules. If you ship the LiPos inside of a housing, they are qualified to be transported under UN3481, which is less restrictive. This is because the housing protects the battery from incidental puncture. For more information in IATA rules, see Battery University <https://batteryuniversity.com> and search for “BU-704a: Shipping Lithium-based Batteries by Air”. If you find IATA shipping is too restrictive, don’t worry: you designed unmodified batteries into your battery pack! Pull the batteries out, and ship the housings empty. Order a new set of LiPos to be delivered to your agent in the foreign port of operation. Open and reassemble the battery pack there.

Commercial firms that offer underwater LiPo batteries:

I haven’t tried charging LiPos under pressure, as one might with a cable-to-shore network, but I suspect they will perform normally.

I hope this was helpful and you’ll explore the cool things LiPos can do for you. Other resources, Books

“Batteries in a Portable World”, Isidor Buchmann, 2016, (ISBN 978-0-9682118-4-7)

“DIY Lithium Batteries”, Micah Toll, 2017, 978-0-9899067-0-8) Future

IEEE Spectrum (October 2022) reported on Mercedes-Benz prototype Vision EQXX sedan. It will sport a “high silicone battery anode…which can squeeze more range from batteries, <and> are widely expected to be popularized over the next decade.” Marine technology often benefits by crossover technologies whose development was paid for by larger markets. In a decade, who knows? Other Shop Talk

Make Magazine, Vol 83, just out, features “2022 Boards Guide”, includes their annual Make: Guide to Boards comparing 79 of the hottest microcontrollers, single-board computers, and FPGAs — with an emphasis on those you can actually get your hands on. Acknowledgements

Thanks to Douglas Alden, R&D Engineer 5, and Dr. Paterno Castillo, Scripps Institution of Oceanography, for engaging the wider Scripps community in a conversation on Lithium batteries through the on-campus Scripps Technical Forum. Thanks also to Chad Collett and Brent Lackey, SubC Imaging (Clarenville, NL, Canada), for their interest and ongoing conversation on undersea LiPo design. The author acknowledges his gratitude to Dr. Peter Worcester, Institute of Geophysics and Planetary Physics (IGPP) at Scripps, recognizing his insatiable curiosity, encouragement, trust in his team, and willingness to try new ways to advance his science. Reader Feedback

Your comments and shared experiences are always welcome. Please send your thoughts, stories and photos to: Kevin Hardy <[email protected]>. You may find yourselves in print!

Garnering power from ocean waves is a generation behind the progress of offshore wind, but Mocean Energy, led by founder…

Van Oord has completed the installation of all 50 foundations and inter-array cables for Baltic Eagle offshore wind farm…

Saab has received a contract from the U.S. Navy for a Double Eagle Semi-Autonomous Remotely Operated Vehicle (SAROV) for…

Taking subsea technology from the workbench to commercialization has always been fraught with hurdles and sinkholes. Synchro…

The navies of Britain, Finland and Estonia were practising subsea infrastructure protection in the Baltic Sea region on Monday…

The organizers of Oceanology International 2024 (Oi24) have invited attendees to discover, connect, and learn, revealing…

Marine Technology Reporter is the world's largest audited subsea industry publication serving the offshore energy, subsea defense and scientific communities.

Lifepo4 Battery Management System Marine Technology ENews is the subsea industry's largest circulation and most authoritative ENews Service, delivered to your Email three times per week